Hello friends ,

we are back with the "design and selecting a proper conveyor belt "topic :

Regarding Belt width: With the optimum belt speed, the determination of the belt width is largely a function of the quantity of conveyed material which is indicated by the design of conveyed belt. In practice the choice and design of a troughing set is that which meets the required loaded volume, using a belt of minimum width and therefore the most economic.

Belt Widths

The belt widths are as follows: 18, 24, 30, 36, 42, 48, 54, 60, 72, 84, and 96 inches.

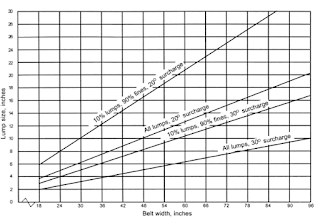

The width of the narrower belts may be governed by the size of lumps to be handled. Belts must be wide enough so that any combination of prevailing lumps and finer material does not load the lumps too close to the edge of the conveyor belt.

Calculation of Belt width: the conveyor capacity may be expressed as loaded volume IVT [m3/h] per v= 1 m/sec. The inclination of the side rollers of a transom (from 20° to 45° ) defines the angle of the troughing. Troughing sets at 40° / 45° are used in special cases, where because of this onerous position the belts must be able to adapt to such an accentuated trough.

To Be Continued.....

Comments

Post a Comment