CXP Vs CXA Heavy Duty Drive Belt

Hello Everyone.....!!!

Today we shall share the difference between Conti CXP & CXA Timing Belt.

Today we shall share the difference between Conti CXP & CXA Timing Belt.

CXP & CXA Rubber Belt Properties:

- Oil resistant to a degree

- Tropics resistant

- UV and ozone

- Electrically conductive (Anti-static) to ISO9563

- Temperatures ranging from -20°C to +100°C

- Increased power ratings

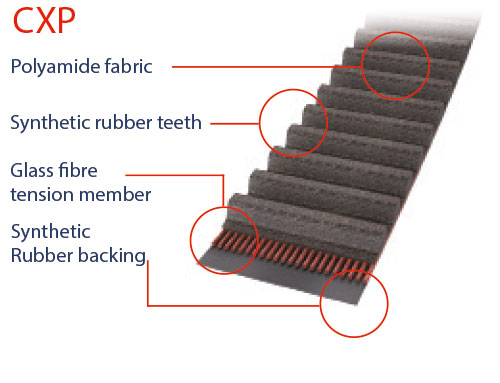

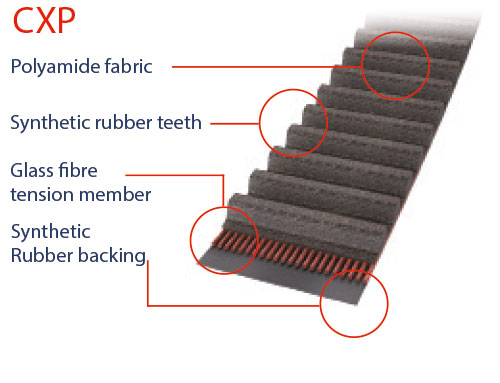

CXP heavy-duty, high speed drive belt

The CXP range has a specifically developed tension member and exceptional material bonding.

The teeth and the belt top are made from a synthetic Rubber mix with high tear resistance and enhanced shear resistance, to ensure reliable sustained power transmission at belt speeds up to 50m/s.

The CXP range is used where high power must be transmitted above 1000RPM.

The teeth and the belt top are made from a synthetic Rubber mix with high tear resistance and enhanced shear resistance, to ensure reliable sustained power transmission at belt speeds up to 50m/s.

The CXP range is used where high power must be transmitted above 1000RPM.

Glass Fibre Tension Member

These tensile members have a high flexural fatigue strength along with a highly reliable power transmission capability up to 50m/s.

CXA heavy-duty, low speed drive belt

The CXA range combines exceptionally high tensile strength with the stable synthetic Rubber compound to transmit extremely high torque levels at belt speeds of up 20m/s. The CXA range is used where high torque must be transmitted under 1000RPM.

Aramid Tension Member

The tensile members strongly resist tension loads and even cope with extremely high starting torques at speeds of up to 20m/s.

Polychloroprene Teeth and Backing

The teeth and the belt top are made from a synthetic rubber mix with high tear resistance and enhanced shear resistance, to ensure reliable, sustained power transmission.

To be contiued......

Comments

Post a Comment